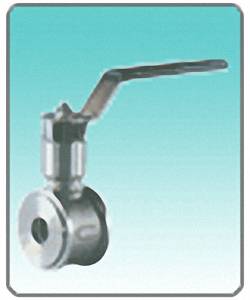

对夹球阀

发布时间 2013-01-24 09:15:47

产品描述

■产品特点

对夹连接球阀具有结构紧凑、密封可靠,重量轻、安装方便、启闭轻构等特点。

■主要零件材料及适用工况

|

主要零件材料 |

阀体 |

WCB |

ZG1Cr18Ni9Ti |

CF8(304) |

CF3(304L) |

ZG1Cr18Ni12Mo2Ti |

CF8M(316) |

CF3M(316L) |

钛 |

|

球阀 |

2Cr13 |

1Cr18Ni9Ti |

0Cr19Ni9 |

00Cr19Ni11 |

1Cr18Ni12Mo2Ti |

00Cr17Ni14Mo2 |

钛 |

|

|

|

密封圈 |

增强聚四氟乙烯、对位聚苯 |

||||||||

|

适用工况 |

适用 |

水、 |

硝酸等 |

强氧化性 |

醋酸等 |

司法部素等 |

醋酸、 |

|

|

|

适用 |

-29-180℃(增强聚四氟乙烯)、-29-300℃(对位聚苯) |

||||||||

|

氧动球阀 |

在相应的手动型号的Q后插入“6”表示,示例:Q671F-16C。氧动装置的氧源压力为0.4-0.7MPa |

||||||||

|

电动球阀 |

在相应的手动型号的Q后插入“9”表示,示例:Q971f-16C |

||||||||

注:1密封圈材料选用对位聚苯,则将型号中密封面材料代号“F”改为“Fs”示例:Q71Fs-16C。

■主要尺寸及重量

|

公称通径DN |

|

尺寸(mm) |

重量(kg) |

||||||||||||

|

mm |

in |

L |

D |

Lo |

H |

手动 |

氧动 |

电动 |

|||||||

|

① |

② |

③ |

手动 |

氧动 |

电动 |

钢 |

钛 |

钢 |

钛 |

钢 |

钛 |

||||

|

15 |

1/2 |

40 |

53 |

47 |

58 |

140 |

80 |

225 |

320 |

0.9 |

0.5 |

4.2 |

3.8 |

7.8 |

7.4 |

|

20 |

3/4 |

45 |

63 |

57 |

63 |

180 |

80 |

228 |

320 |

1.3 |

0.8 |

4.5 |

4 |

8.2 |

7.8 |

|

25 |

1 |

50 |

73 |

66 |

74 |

180 |

100 |

235 |

340 |

1.6 |

1.0 |

5.8 |

5 |

8.6 |

8 |

|

32 |

1/4 |

60 |

84 |

75 |

84 |

200 |

110 |

260 |

350 |

2.6 |

1.5 |

9.0 |

8 |

9.5 |

8.4 |

|

40 |

1/2 |

70 |

94 |

85 |

89 |

200 |

120 |

270 |

360 |

3.8 |

2.2 |

10.5 |

8.5 |

11 |

9.4 |

|

50 |

2 |

80 |

109 |

103 |

104 |

250 |

130 |

280 |

370 |

5 |

3.0 |

11.5 |

9.5 |

12 |

10 |

|

65 |

2/2 |

110 |

129 |

122 |

124 |

300 |

140 |

360 |

380 |

7.5 |

4.5 |

26.5 |

23.5 |

14.5 |

11.5 |

|

80 |

3 |

120 |

144 |

135 |

134 |

350 |

150 |

380 |

450 |

11 |

6.5 |

30 |

25.5 |

45 |

40.5 |

|

100 |

4 |

140 |

164 |

173 |

159 |

450 |

180 |

420 |

490 |

17 |

10 |

38 |

31 |

51 |

44 |

注:1为PN1.0、1.6、2.5MPa球阀的数值,其中PN2.5MPa,DN100的D值为170;2为PN2.0MPa、Class150球阀的数值;3为10K球阀的数值。

■型号及主要参数

|

配管法兰 |

公称压力 |

产品型号 |

|||||||

|

JB/T74-90 |

PN1.0MPa |

Q71F-10C |

Q71F-10P |

Q71F-10P8 |

Q71F-10P3 |

Q71F-10R |

Q71F-10R8 |

Q71F-10P3 |

Q71F-10Ti |

|

PN1.6MPa |

Q71F-16C |

Q71F-10P |

Q71F-16P8 |

Q71F-16P3 |

Q71F-16R |

Q71F-16R8 |

Q71F-16P3 |

Q71F-16Ti |

|

|

PN2.5MPa |

Q71F-25 |

Q71F-25P |

Q71F-25P8 |

Q71F-25P3 |

Q71F-16R |

Q71F-25R8 |

Q71F-25P3 |

Q71F-16Ti |

|

|

GB9112-9131 SH3406 |

PN2.0MPa |

Q71F-20C |

Q71F-20P |

Q71F-20P8 |

Q71F-20P3 |

Q71F-20R |

Q71F-20R8 |

Q71F-20P3 |

Q71F-20Ti |

|

ANSI B16.5 |

Class 150 |

Q71F-150(LB)C |

Q71F-150(LB)P |

Q71F-150(LB)C8 |

Q71F-150(LB)C3 |

Q71F-150(LB)R |

Q71F-150(LB)R8 |

Q71F-150(LB)C3 |

Q71F-150(LB)Ti |

|

JIS B2212 |

10K |

Q71F-10(K)C |

Q71F-10(K)P |

Q71F-10(K)P8 |

Q71F-10(K)P3 |

Q71F-10(K)R |

Q71F-10(K)R8 |

Q71F-10(K)R3 |

Q71F-10(K)Ti |

注:1密封圈材料选用对位聚苯,则将型号中密封面材料代号“F”改为“Fs”示例:Q71Fs-16C。